Description

Laser alignment is an esential component of a viable maintenance strategy for any machines. The ultimate goal of a sheave alignment system is to reduce unexpected machine failure by taken a proactive maintenance approached that will not only identify certain problems but also allows extending machine operating life.

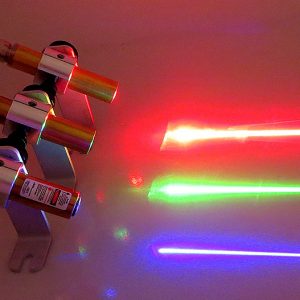

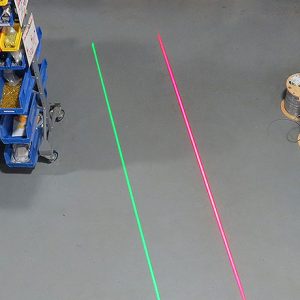

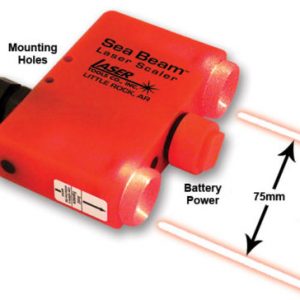

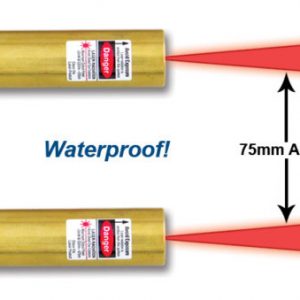

Align Sheaves and Pulleys with a “Laser Beam”. This means you now have faster set-ups, more accurate adjustments and minimum machine down time.

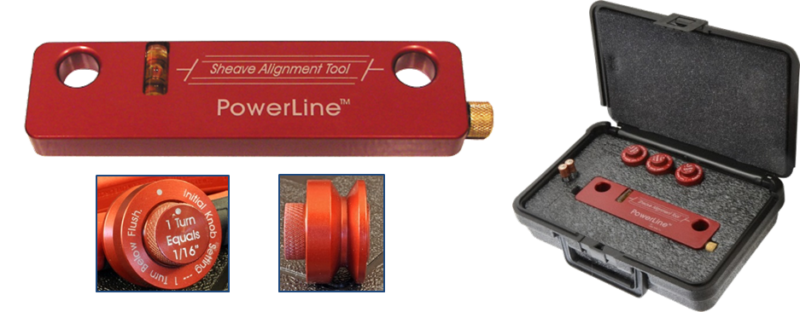

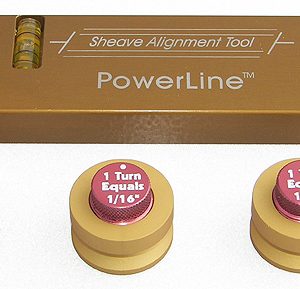

Align sheaves, belts, platforms, conveyors and soft motor mounts. Works with belt, gear and roller transmission systems too! The flat Laser Line can also be used as a level layout reference. The Model L80 Sheave Alignment System includes: PowerLine© Pulley Alignment tool with Laser Beam accuracy, 3 adjustable targets, and hard shell carrying case.

- Minimize belt wear

- Less down time

- Quick and easy alignment checks.”

- Real” time adjustments

- Adjust belts under normal load conditions

- Insure proper belt tension.

- positive tracking

How It Works

The PowerLine© Pulley Alignment tool projects a plane of laser light parallel with the faces of drive and driven pulleys. Adjustable targets attach to the pulleys, intersect the laser beam and visually show any misalignment. With this “Positive Tracking”, alignment adjustments can be made in “Real Time” by only one person!

Also available is the optional L80K Sheave Alignment System with Krikit® I tension tester for belt tensions up to 150lbs.

Reviews

There are no reviews yet.