Industries Served

Getting the precision and accuracy machines need to perform better isn’t easy though, as parts – more often than not – need to be manufactured to within a millimeter of the desired design specifications. Fortunately, the CNC machine manufacturing services of Laser Tools makes the task much easier to achieve, as it uses the pinpoint exactness of laser technology to create the best parts possible.

Every machine, regardless of how complex, is nothing more than a giant puzzle; every piece does its part to complete the picture, but they all need to fit just right to work. Creating the right pieces doesn’t seem like such a difficult task, but success in the machining industry is measured in millimeters, and it doesn’t take much to lose the top spot.

The continuous presence of the Laser Tools name among the top CNC machine manufacturers in the industry is a testament to the quality and consistency of our services. The machines that will eventually get the parts that we create will be able to work so flawlessly that the operators would swear that it came from the factory. The significance of this praise isn’t lost on us, as we strive to continue to exceed expectations with each of our machined parts.

Don’t waste any more time getting the right CNC machine parts manufacturers that can give you the parts you need, because we’re right here. Contact us today, and we’ll answer every question you might have regarding our services.

From an idea to an ideal! here’s how…

You provide the idea for a part, sub-assembly or finished concept, and we supply the means and the design.

— Your idea is presented to our engineers and design specialists.

— We design your part, components or subassemblies.

— We fabricate all prototypes using CNC mill and lathe protocols to the precision required.

— We provide production estimates and schedule lead times for your market needs.

It’s that simple!

The trick is to bring together the best talent early on in the design process. This saves time and money and produces superior parts that work, fit together or exceed the practical tolerances required.

Production

CNC Mills and Lathes do the real production fast and accurately.

— Precision parts can be made to close tolerance and reproduced in volume

— CNC Production schedules and lead times can be forecast with greater accuracy and more assurance.

— Quality control and assurance procedures use Go/No Go gauge systems for a best fit manufacturing approach.

— Optional 100% parts testing produces zero defects for TQM and 6 Sigma profiles.

— Production fixtures are designed on site for parts placement and machine loading. This increases machining throughput.

Prototypes and first run production samples are necessary for tangible review, dimension accuracy, fit and finish and proof of concept. There is always a “First Part”.

Both manual and CNC mills are used for prototype production and proof of concept results. This ensures more reasonable setup costs.

Product Assembly Service

Laser Tools Machining has the manpower and expertise to assemble intricate parts and components into complete sub-assemblies including finished products. We can package, inventory and ship worldwide items for wholesale and retail distribution. Laser Tools Machining is a division of Laser Tools Co., Inc. that has 20 years experience in sales and marketing industrial and commercial products and services.

— Individual Go/No Go testing of machined parts to design specifications

— Assembly of parts and components by technically trained personnel

— Complete parts testing and calibration of component and sub-assemblies.

— Package and shipping to customer specifications including labeling and part number IDs

— Documentation and Certificates of Compliance provided as required.

Machining: Basic parts are machined on manual and automatic CNC (Computer Numerically Controlled) Mills and Lathes. This includes prototypes, preproduction samples and small run parts.

Both Manual and Computerized machining are used for best end results. Prototype parts and small runs are often created using our manual milling approach and 40 years of machining experience. Knowing the correct “Feed and Speed” is using knowledge gained from experience. This is applied to all parts machined at Laser Tools Machining.

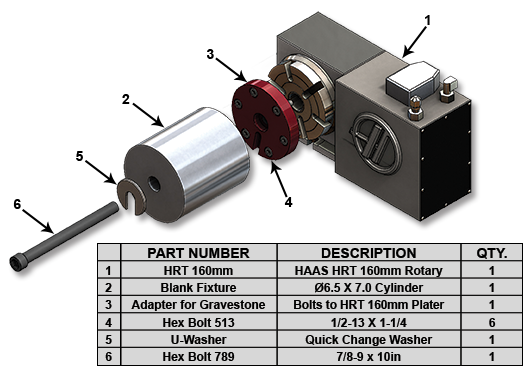

The GRAVESTONE™ Quick Change Fixturing System

The GRAVESTONE™ work holding fixture is comparable to a horizontal milling center tombstone and fits any Haas HRT 160mm rotary platter. Increase productivity compared to conventional vertical milling center work holding methods. These fixtures are constructed of 7075-T6 aluminum and are available as a “DIY” template or a custom solution tailored to your needs.

Services

Ensure quality and precision in every machining project with Laser Tools, Inc.

When it comes to laser tools machining services in Arkansas, we’ll pinpoint you in the right direction through our unmatched products and services. Laser Tools, Inc. ensures precision and accuracy in all manufactured parts to give customers only the best possible quality.

On Point Every Time

As a leading provider of laser tools machining services in Arkansas, it is our goal to help customers achieve sustained success by delivering top quality products. Advanced, world-class technology combined with our highly experienced team is what we use to deliver great results.

We manufacture precision parts quickly and with great accuracy. You can trust that we do things on point the first time, every time. Our CNC mills and lathes allow us to produce parts to close tolerance and in volumes. Trust that the last unit that comes out of our machines will be the same as the first one, and everything in between.

We can manufacture any precision parts and tools you need. Simply give the idea for a part, sub-assembly, or finished concept, and our team of engineers and designers will work with you to come up with a plan and prototype.

Our team will design the part, component, or assembly, come up with estimates and schedules, fabricate a prototype, and when everything is in order, we’ll start production to the required precision using CNC mill and lathe protocols.

We predict production schedules and lead times with greater accuracy and more assurance. Quality control is also never an issue, as we use a Go/No Go gauge system for a best fit manufacturing process. Our optional 100% parts testing process produces zero defects for TQM and 6 Sigma profiles.

Get accurate machining for your company or organization with us. Trust Laser Tools, Inc. for laser tools machining services in Arkansas. We ensure you have the right parts, tools, and equipment for the job.

Arkansas Metal Machining

The combination of confidence, knowledge, and experience is the secret behind the expertise of the technicians that work with us at Laser Tools. The metal machining services that we offer are among the best in the industry, as we’re more than capable of dealing with even the most complex precision turned metal instruments.

This is not an easy industry to thrive in, as the demands and expectations of clients rise with each successful order. The schematics of each part become more specific, the timetables get stricter, and the significance of the parts becomes more vital. Fortunately, we’re more than ready for the increase in responsibility that our clients trust us with, as we have enough years at the helm of such projects to know what we’re doing.

Any company that requires metal machining services shouldn’t waste their time shopping for affordable deals with less experienced machinists and technicians. Too many significant factors depend on the performance of their products to leave to chance. If you need a specific replacement part that can effectively step into the shoes of the original, go straight to the best people in the business.

We have the track record to prove to potential clients that we’re the people they need to talk to for all of their milling and machining needs. Our experienced technicians and machinists have been in the service of aerospace, automobile, mining, as well as oil and gas companies. Laser Tools is a name that has earned the trust of several top-tier businesses, as well as showing proficiency in understanding the nuances of highly technical fields.

If you want the job done right the first time, we’re the people you need to talk to for all your metal machining needs and requirements. We’ll work closely with you to ensure that we have all the right information regarding what you want to happen with the part, and then execute the production of the part to perfection.

Arkansas CNC Milling

Laser Tools is one of the leaders in the CNC milling services industry, with years of experience in serving a variety of industries. These businesses include the largest companies in aerospace, automotive, marine, and the oil and gas industries. The pressure to get everything right is immense, but it’s something our highly skilled technicians are more than capable of handling.

Every one of our technicians have years of knowledge and experience to fall back on for every task they’re given. There’s almost nothing that any of our clients can throw at them that they haven’t seen before. This is the kind of confidence that allows them to create pieces with the precision and speed that our clients have grown accustomed to.

We don’t just rely on people for our work though, as we also have the latest tools in machining technology to help us measure how close our estimates are to the specifications the client needs. There are very few other machining services that can say they excel in both the use of their machines and manpower, which gives us a potent combination. This marriage of human skill and mechanical accuracy is the reason our CNC milling services remains consistent as one of the best in the business.

Laser Tools isn’t a company content to rest on its laurels though, as we understand that the march of technology and techniques is an ongoing process. This is the reason we continuously keep training and re-training our technicians to ensure that their skills and knowledge remain fresh in their minds. Doing this also allows us to bring them up to speed on the latest machines available in the market that they may be working with in the near future.

Explore the rest of our website for the other CNC milling services we offer. Don’t hesitate to contact us as well; we’ll work closely with you to get the part you need for any job or project.