Description

A good sheave alignment laser system will increase efficiency by reducing premature wear or failure of pulleys, belts and bearings. There are several different alignment methods, such as the labor intensive string and straight hedge method, however, laser alignment seems the more accurate. This will greatly reduce downtime and manpower needed to do the alignment. This results in increased production up time and great labor savings.

“You know you’re aligned when the green line glows.”

– Ron Dinwiddie, Production Manager

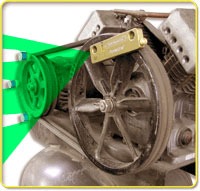

Introducing new Retro-Reflective alignment targets that work indoors or outdoors using enhanced reflective technology. This means that the laser lines can be seen better in direct sunlight and adjustments are easier to make.

- Faster Set-ups

- More Accurate Adjustments

- Less Bearing Wear

How it works

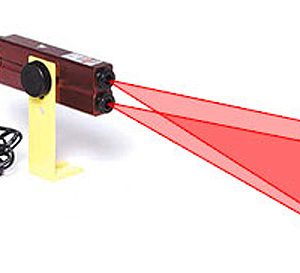

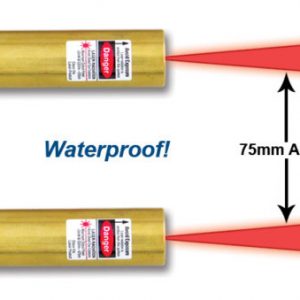

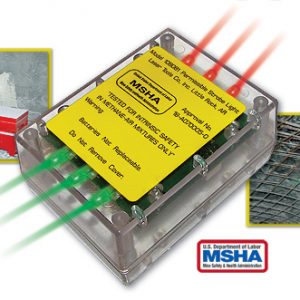

The PowerLine™ sheave alignment tool projects a plane of laser light parallel with the faces of drive and driven sheaves. Adjustable targets attach to sheaves, intersect the laser beam and visually show any misalignment. The Retro-Reflective film on the center line of the target reflects the laser beam and “glows” for enhanced visibility and accuracy. The reflective green film shows the laser’s alignment line in “Real Time”. This is called “Positive Tracking”.

- Decrease Vibration – Minimize Belt and Motor Bearing Wear.

- Compact Size – Easy to use on small diameter sheaves.

- 10 Times Brighter – Can be used in direct sunlight

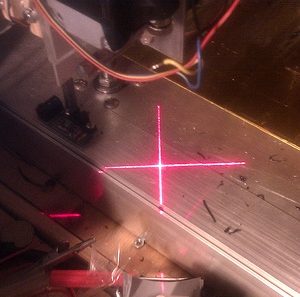

- Use as a laser level – Check the height and flatness of motor and gear box mounting plates.

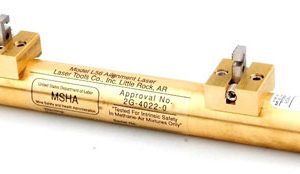

Model GL80 Green Laser Technology™ Sheave Alignment System

- Includes

- GL80 PowerLine™ Sheave Alignment Tool

- 3 – Retro-Reflective, Adjustable Alignment Targets

- 1 – Foam Filled, Hard Carrying Case

- Optional Tension Testers: KriKit® I & II tension testers. 0-300 Lbs.

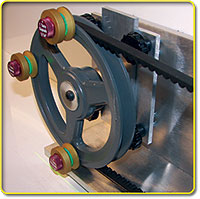

Model GL80 Sheave Alignment Trainer

Shown with the GL80 Green Laser Technology™ Sheave Alignment Laser and Retro-Reflective Target System. Use this trainer to understand sheave alignment and reduce belt, sheave and bearing wear.

- Reduces Downtime

- Lowers Operating Costs

- Repairs Equipment Faster

- Lowers Training Costs

- Promotes Laser Alignments

Also available is the optional GL80K Sheave Alignment System with Krikit® II tension tester for belt tensions from 100lbs to 300lbs.

Reviews

There are no reviews yet.