Description

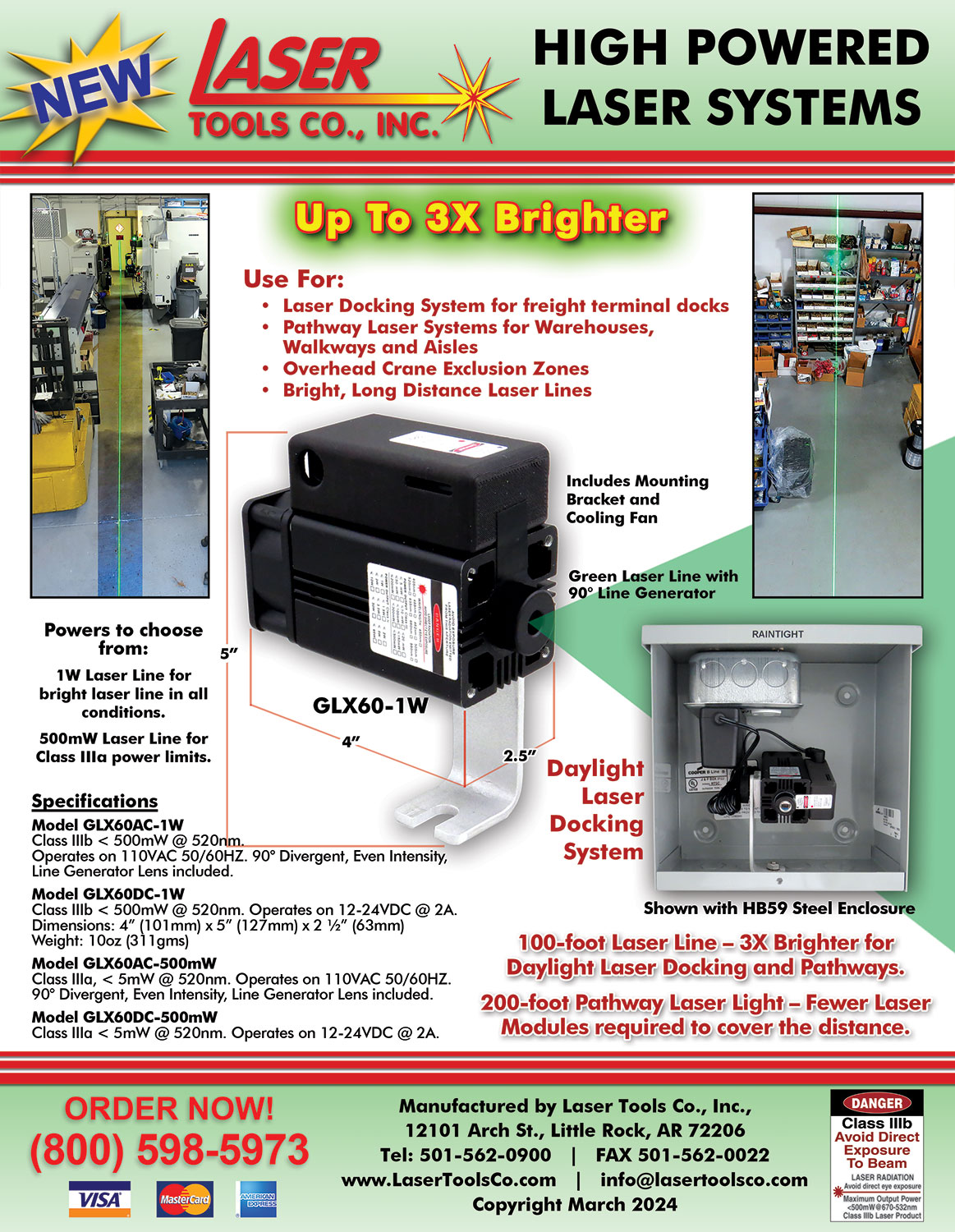

GLX LASER DOCKING SYSTEM™ “WORKS IN DIRECT SUNLIGHT”

High Powered Laser Now 3x Brighter!

“Green Laser Runway Lights for Freight Terminals and Warehouses”

Laser guide lights that help truck drivers back down centered to freight docks can now be seen in direct sunlight. Laser Tools Co. has introduced “Directed Energy” high powered laser light that can be seen on each side of the freight dock in bright sunlight.

This means:

- Eye safe, visible laser guide lights are viewed in the driver’s wing mirrors.

- The laser guide lights can be seen over 150 feet away in direct sunlight.

- The back of the trailer can be centered between the laser guide lights.

- Laser guide lines are still viewable on the ramp or tarmac in low light, rain, snow, mud, or overcast conditions.

4 High Powered Laser Docking System Models to Choose From

Each complete Laser Tools Co., Inc. Laser Docking™ System includes the following:

- GLX60AC-500mW Class IIIa Daylight Laser Docking System Includes

- 2-GLX60AC-500mW Laser Modules with cooling fan.

- Large Angle Line Generator Lens

- 2-AP94 Mounting Brackets

- 2-HB59 Steel Enclosures with front exit windows.

- 110VAC @ 1.5A power required

- Class IIIa < 5mW @ 520nm

- 2-12″ cables with AC adapters for input power of 90VAC to 230VAC, 50/60HZ

- GLX60DC-500mW Class IIIa Daylight Laser Docking System Includes

- 2-GLX60AC-500mW Laser Modules with cooling fan

- Large Angle Line Generator Lens

- 2-AP94 Mounting Brackets

- 2-HB59 Steel Enclosures with front exit windows

- 12-24VDC @ 2A power required

- Class IIIa < 5mW @ 520nm

- Terminal Strip for input power of 12VDC to 24VDC

- GLX60AC-1000mW Class IIIb Daylight Laser Docking System Includes

- 2-GLX60AC-500mW Laser Modules with cooling fan.

- Large Angle Line Generator Lens

- 2-AP94 Mounting Brackets

- 2-HB59 Steel Enclosures with front exit windows

- 110VAC @ 1.5A power required

- Class IIIb > 5mW @ 520nm

- 2-12″ cables with AC adapters for input power of 90VAC to 230VAC, 50/60HZ

- GLX60DC-1000mW Class IIIb Daylight Laser Docking System Includes

- 2-GLX60AC-500mW Laser Modules with cooling fan.

- Large Angle Line Generator Lens

- 2-AP94 Mounting Brackets

- 2-HB59 Steel Enclosures with front exit windows

- 12-24VDC @ 2A power required

- Class IIIb > 5mW @ 520nm

- Terminal Strip for input power of 12VDC to 24VDC

Optional: Remote Control with FOB Transmitter and Receiver. Use with Model GLX60 Laser Docking Systems.

Loading Dock Laser Guide Beams

This is why Laser Tools Co.’s Laser Docking™ System is the perfect trailer docking assistant. A driver can “see” the laser docking lines in his wing mirrors when the truck and trailer are approaching the docking lane. This guides the driver while backing up to the loading dock. Also, the laser lines provide a visual indication that the trailer is centered to the loading dock.

How a Laser Docking™ System Works

If you shine a laser beam onto a floor, you’ll see a dot. If you install line generating optics, the dot will turn into a line. But viewing the dot or line from the point of view beside or behind the laser is not totally revealing. If you stand in front of the laser line generator module and look at the laser line, the increased brightness is noticeable. This is because you are viewing the incident light reflected off of the floor. Also the viewable line is much longer. This means that the brighter laser line can be seen in low ambient light conditions and farther away from the laser module itself.

Reviews

There are no reviews yet.