The L80 Sheave Alignment Laser System — Why “Made in the U.S.A.” Matters for Safety

Why “Made in the U.S.A.” Matters for Safety

There is a perception that a product designed, manufactured, assembled and sold in the U.S. is a better product. Naturally, this is arguable since merchandise, durable goods, food and necessities are available worldwide. This is the “Macro” big picture point of view. But, if a narrow focus on just one industrial product is analyzed, including the features that can be defined to create perceived value and support the emotional perspective, then U.S. made products are historically better.

Let’s use the L80 Sheave Alignment System as an example and outline some specific areas that give it high perceived value.

The L80 Sheave Alignment Laser from Laser Tools Company

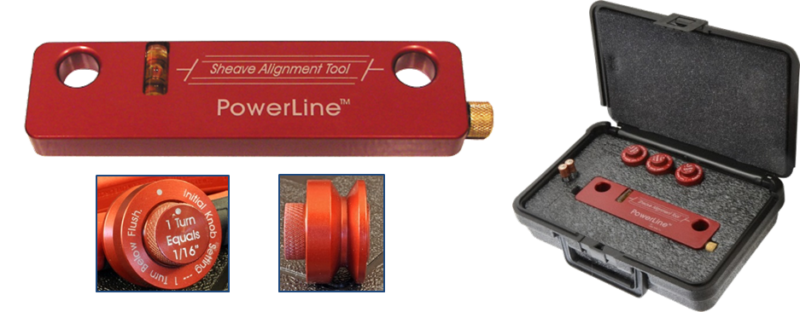

L80 with Red Laser Technology, with Krikits cased PowerLine and targets

In industries where belt-driven systems are common, used by maintenance technicians, reliability engineers, and plant operators, precision is not a luxury — it is a necessity. When crews are working thousands of feet above ground, often under demanding environmental conditions, the reliability of their tools directly impacts safety, efficiency, and project success. That’s why the L80 Sheave Alignment Laser “Powerline™”, designed, manufactured, and assembled in the United States, stands apart as a critical investment for so many “get your hands dirty” professionals.

Precision You Can Trust — Built at Home

The L80 Sheave Alignment Laser was engineered specifically for industrial industries, with input from experienced professionals. Unlike generic alignment tools or imported alternatives, the L80 is purpose-built to deliver accurate, repeatable results when aligning power transmission systems.

The internal electronics are designed, manufactured and supplied by vendors in the U.S. This means that the quality, reliability and availability of this part is controlled. Note that cost is the least important consideration in comparison to a non-U.S. supplier like China, India or Mexico. Foreign suppliers believe that low cost is primary to success and directly related to selling price. This is incorrect. The performance of an item is paramount to cost. This underlining principle motivates the circle of people that produce the L80 Sheave Alignment System. This means that all parties involved must be able to communicate purposefully and understand all the elements that create the L80 Sheave Alignment System’s Perceived Value to the market place.

The L80 Sheave Alignment System must perform and do the job well. This means that the “PowerLine™” Laser Tool and adjustable magnetic targets must work together to satisfy the millwright (End User) who’s using the product. The End User must be emotional satisfied…and that defines to the End User the true meaning of Perceived Value!

By designing and manufacturing the L80 Sheave Alignment Laser in the U.S.A., Laser Tools Company maintains strict quality control at every stage of production. From optical alignment and laser calibration to housing durability and final assembly, every detail is closely monitored. The result is a tool that performs consistently in the field — job after job.

GL80 with Green Laser Technology, with Krikits cased PowerLine and targets

Why U.S. Manufacturing Makes a Real Difference

Choosing a U.S.-made sheave alignment tool is about more than patriotism — it’s about performance, safety, and accountability.

For example, all the parts of the L80 Sheave Alignment Tool which are designed, manufactured, anodized (the color and finish) and inspected before assembly in-house and by Laser Tools Co. personnel. This means that any variance in the build process can be detected early in the manufacturing process and corrected immediately, ensuring the highest standards of quality control. This is much more efficient and faster when producing a high quality product. Consumers are trained to expect quick deliveries like Amazon and Wal Mart “at your door” deliveries. Back orders mean canceled orders. The L80 Sheave Alignment System is built using a vertically integrated manufacturing approach that controls all the processes to deliver an L80 Sheave Alignment System built from raw goods and delivered to the end user fast.

- Superior Quality Control

Domestic manufacturing allows Laser Tools Company to enforce rigorous testing standards that are difficult to guarantee with overseas production. Each L80 unit is inspected and calibrated to meet exact specifications before it reaches the customer. - Built for Harsh Jobsite Conditions

Powerline work demands equipment that can handle vibration, temperature extremes, dust, and moisture. The L80 is built using durable materials and robust construction methods proven in real-world utility environments across the United States. - Faster Support and Service

When tools are manufactured and assembled domestically, replacement parts, service, and technical support are significantly faster. This minimizes downtime and keeps crews productive when schedules are tight. - Compliance and Consistency

U.S. manufacturing ensures consistency in materials, electronics, and laser components — critical for maintaining accuracy and compliance with industry expectations and safety standards.

Safety Starts with Alignment

Proper sheave alignment is essential for preventing belt damage, reducing drag, and ensuring smooth power transmission. Misaligned sheaves can lead to excessive wear, costly rework, and potential safety hazards.

The L80 Sheave Alignment Laser provides a clear, highly visible reference line that allows crews to quickly verify and correct alignment. This not only improves efficiency but also helps protect both equipment and personnel — an outcome that directly supports utility safety programs.

Supporting American Workers and Industry

When you purchase the L80 Sheave Alignment Laser, you’re also supporting American manufacturing jobs, skilled technicians, and domestic innovation. Laser Tools Company’s commitment to U.S. production strengthens the supply chain, reduces dependency on foreign manufacturing, and ensures long-term product availability.

For utilities and contractors who prioritize reliability, safety, and responsible sourcing, this commitment matters.

A Smart Investment for the Long Term

In an industry where tool failure can delay projects and compromise safety, the L80 Sheave Alignment System represents a smart, long-term investment. Its U.S.-based design and manufacturing translate into:

- Greater reliability in the field

- Longer service life

- Trusted accuracy

- Responsive customer support

Choose Precision. Choose Reliability. Choose U.S.A.